dot type7a drop testing|drop test orientation : inc A Type 7A package, with its contents, must be capable of withstanding a free drop test. The specimen must drop onto the target so as to suffer maximum damage to the safety .

Resultado da Conta Globo - Login - E-mail. Sua conta para tudo na Globo. E-mail. Continuar. Ou escolha a opção.

{plog:ftitle_list}

WEBLogin. Data de Nascimento. Cancelar Resgatar Senha. Email enviado! OK. www.supercentro.prefeitura.rio. OK. Este site armazena informações de sessão localmente em seu próprio navegador pelo uso da local storage API e session storage API que são essenciais para fornecer serviços disponíveis e permitir que possa usar determinados .

In addition to meeting the requirements of § 173.465(c)(4), “for cylindrical fiberboard packages with a mass of 100 kg (220 pounds) or less, a separate specimen must be subjected to a free .

поточный влагомер удвн

§ 178.603 Drop test. (a) General. The drop test must be conducted for the qualification of all packaging design types and performed periodically as specified in § 178.601 (e). For other . The Department of Transportation requires that packaging designed to transport Type A materials undergo a battery of tests to simulate .operating contractors, an evaluation and testing program to qualify Type A radioactive material packagings per U.S. Department of Transportation (DOT) Specification 7A (DOT-7A) of the .

packing group ii drop test

The purpose of this compliance checklist is to ensure DOT 7A Type A packages procured for use on the Hanford Site comply with the U.S. Department of Transportation . A Type 7A package, with its contents, must be capable of withstanding a free drop test. The specimen must drop onto the target so as to suffer maximum damage to the safety .

Specifically, closure testing is performed varying: 1) the amount of torque applied to the closure ring bolt; and, 2) stress relief protocol, including: a) weight of hammer; and, b) . As part of this effort, a series of physical drop tests and FEAs were conducted at SRNL. These tests used Skolnik drums, CQ5508L (see Attachment 1), which are open DOT . The purpose of this document is to provide guidance for qualifying a DOT-7A Type A packaging for use. WHC qualifies DOT-7A packaging for two purposes. The first is to provide packages for use by WHC (manufacturer .The Savannah River National Laboratory (SRNL) is in the process of developing recommendation for the U S. Department of Energy contractors and vendors who want to qualify drums as U S. .

drop test orientation chart

drop test orientation

(a) The packaging, with contents, must be capable of withstanding the water spray, free drop, stacking and penetration tests prescribed in this section. One prototype may be used for all tests if the requirements of paragraph (b) of this section are met. The tests are successful if the requirements of § 173.412(j) are met. (b) Water spray test. The water spray test must precede .

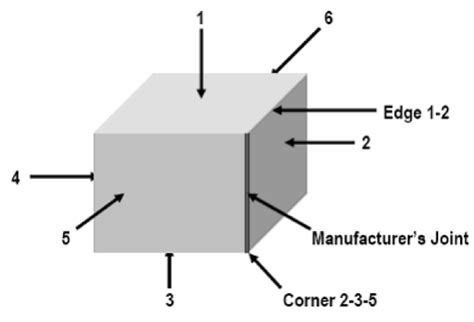

(a) General. The drop test must be conducted for the qualification of all packaging design types and performed periodically as specified in § 178.601(e).For other than flat drops, the center of gravity of the test packaging must be vertically over the point of impact. Where more than one orientation is possible for a given drop test, the orientation most likely to result in failure of the .

The drop test must be conducted for the qualification of all packaging design types and performed periodically as specified in § 178.601(e). For other than flat drops, the center of gravity of the test packaging must be vertically over the point of impact. Where more than one orientation is possible for a given drop test, the orientation most .

This test procedure documents the steps involved with performance testing of Department of Transportation Specification 7A (DOT-7A) Type A packages. It includes description of the performance tests, the personnel involved, appropriate safety considerations, and the procedures to be followed while performing the tests.(b) Each Specification 7A packaging must be marked on the outside “USA DOT 7A Type A.” (c) Each Specification 7A packaging must comply with the requirements of §§ 178.2 and 178.3. In § 178.3(a)(2) the term “packaging manufacturer” means the person certifying that the package meets all requirements of this section. The purpose of this document is to provide guidance for qualifying a DOT-7A Type A packaging for use. WHC qualifies DOT-7A packaging for two purposes. The first is to provide packages for use by WHC (manufacturer-qualified). The second is to provide a contracted service in support of DOE/EM-76 (DOE-qualified). This document includes descriptions of the . Specifically, closure testing is performed varying: 1) the amount of torque applied to the closure ring bolt; and, 2) stress relief protocol, including: a) weight of hammer; and, b) orientation that the hammer hits the closure ring. . Recommendations for DOT 7A Type A Drum Closure and Drop Testing with Additional 49 CFR 173.465(c)(2) Testing .

container may be recycled from excess DOE stock. This design has passed the drop testing for Department of Transportation (DOT) Type 7A specifications and the U.S. Nuclear Regulatory Commission (NRC) Type B specifications for shipping in the HalfPACT transportation container. The drop tests demonstrated that there will be noThey have also passed rigorous water spray, free drop, penetration and stacking tests. Skolnik can manufacture custom designs in both carbon and 304, 316 and 409 stainless steel. Our in-house test lab can also perform surrogate 7A Type A tests per your specifications. Skolnik does not, and cannot, certify this packaging as a DOT 7A Type A package.

7 B-1000 Compactor •egative pressure HEPA filtered N • World-leading suppliers • Designed around the B-1000 container • ASTM A-500 structural tubing and ASTM A-36As part of MRC-Mound's responsibility to coordinate DOE Spec 7A Type A Packaging testing, evaluation, and utilization, this document evaluates per 49CFR 173.415(a) the SWEPP packaging system: DOT Spec 17C steel drums - 30, 55 and 83-gal; High Density Polyethylene (HDPE) liners; and SWEPP DVS Filter Assemblies (two configurations) as a US DOT Spec 7A Type A .

Standard DOT 7A Type A Packaging Compliance Checklist . DOT 7A TYPE A PACKAGING COMPLIANCE CHECKLIST FOR:_____ 1.0 PURPOSE AND SCOPE . The purpose of this compliance checklist is to ensure DOT 7A Type A packages procured for use on the Hanford Site comply with the U.S. Department of Transportation (DOT) regulations We take great care to manufacture our products thicker, heavier and stronger than industry standards require and to rigorously test the final products. We water spray, free drop, penetration and stack test our drums and our house test lab can even perform surrogate 7A Type A tests per your specifications.Program (DP -4) and later as the “Test an d Evaluation Document for DOT Specification 7A Type A Packaging” by Westinghouse Hanford Company in Richland, Washington. Most of the historic testing (i.e., circa 1970) assumed that the most unfavorable orientations were . Historic Drop Testing Orientations : Based on these concerns (i.e., circa .

The system meets DOT 7A Type A packaging requirements. Inside the bag are Dose Pigs, model number 001-280, which are designed to reduce exposure from gamma emitting radiopharmaceuticals. The barrel of the . FREE DROP TEST: Two drop tests were performed from 30 Feet and 4 Feet, test were conducted according to 49 CFR 173.465 (a) and IATA 10.6 .

dot 7a type a requirements

By combining the split cavity design with large diameter tubing and diagonal cross bracing, drop test requirements of 49CFR173.465(1) and (2) were met and demonstrated through finite element analysis modeling. . Recommendations for DOT 7A Type A Drum Closure and Drop Testing with Additional 49 CFR 173.465(c)(2) Testing and Analysis.ISDI/RIPA Testing Procedures Manual 6 IV. Testing and Recordkeeping, General Introduction It is the responsibility of the container manufacturer (or “re-manufacturer”*) to perform and document design qualification testing, periodic retesting, and “production testing” in accordance with 49 Code of Federal Regulations (“CFR”)The US Department of Energy (DOE) has been conducting, through several of its operating contractors, an evaluation and testing program to qualify Type A radioactive material packagings per US Department of Transportation Specification 7A (DOT-7A) of the Code of Federal Regulations, Title 49, Part 178, Section 178.350 (49 CFR 178.350). It is your understanding that center of gravity over impact point testing is not a required drop test orientation for a Type 7A package, unless such an orientation would impart maximum damage to the package. . 202-366-4595 or [email protected] Pipeline Safety Concerns or Feedback on our Performance and Conduct: 202-366-4595 or .

This test report documents the performance of Savannah River National Laboratory’s (SRNL’s) U.S. Department of Transportation (DOT) Specification 7A; General Packaging, Type A shielded liquid shipping packaging and compliance with the regulatory requirements of Title 49 of the Code of Federal Regulations (CFR).

DOT 7A Type A.’’ (c) Each Specification 7A packaging must comply with the requirements of §§178.2 and 178.3. In §178.3(a)(2) the term ‘‘packaging manufacturer’’ means the person certifying that the package meets all requirements of this section. [Amdt. 178–109, 60 FR 50336, Sept. 28, 1995; 60 This evaluation and testing program is called the DOT-7A Program. When an applicant has determined that a DOT-7A packaging is needed and not commercially available, a design may be created according to this document. The design should include a packaging drawing, specifications, analysis report, operating instructions, and a Packaging . The purpose of this guide is to provide instruction for assuring that the regulatory design requirements for a DOT-7A Type A packaging are met. This guide also supports the testing and evaluation activities that are performed on new packaging designs by a DOE-approved test facility through the DOE`s DOT-7A Test Program.

This document is a support document for the ''DOE Evaluation Document for DOT 7A Type A Packaging,'' MLM-3245, March 1987. Provided herein are details concerning the performance requirements specified in 178.350 Specification 7A, General Packaging, Type A. MLM-3245 references appropriate sections in this document. . Test and evaluation .Based on U.S. DOT and NRC regulations in effect on October 1, 2015; Rev. 2 Contacts: DOT – [email protected]; NRC – [email protected] . 1. Minimum Required Packaging for Class 7 (Radioactive) Material: [1] (49 CFR 173 and 10 CFR 71) [2] These are basic reference charts; refer to current U.S. DOT and NRC regulations for complete . The twenty two design requirements from 49 CFR 173.411 and the nine environmental and test conditions from 49 CFR 173.465 and 49 CFR 173.466 are addressed in the testing program. The containment system was shown to be capable of preventing the loss or dispersal of radioactive contents as well as preventing any increase in radiation levels at . Evaluation and testing activities on 1208 three DOT-7A Program Dockets resulted in the qualification of three new packaging configurations, which are incorporated herein and summarized. This document presents approximately 300 different packagings that have been determined to meet the requirements for a DOT-7A, type A packaging per 49 CFR 178. .

dot 7a type a packaging

WEBThis is a subreddit for comics of rule 34. No pics or gifs just comics. MembersOnline. •. SuccotashAdditional9. ADMIN MOD. My Hero: Part 1 (My hero academia) [Artist: Jay Marvel] True R34. Share Add a Comment.

dot type7a drop testing|drop test orientation